Static O-Ring Design Options

There are five types of static o-ring applications: Flange seal, Radial seal, Dovetail seal, Boss seal and Crush seal.

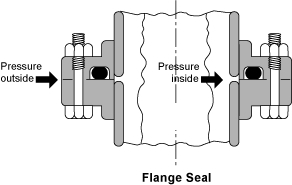

Flange Seal

In flange seal glands, the two flanges are assembled with metal to metal contact. So in fact there is no remarkable gap and no risk for extrusion of the O-ring as long as the construction does not deform under system pressure.

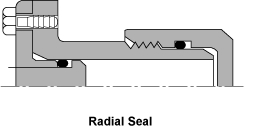

Radial Seal

Because the metal parts are pressed or screwed together there is always a clearance gap with risk for extrusion.

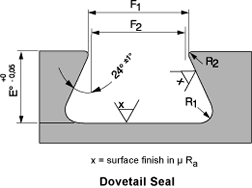

Dovetail Seal

Also here there is a metal to metal contact as long as the construction will not deform under system pressure.

Boss Seal

The groove dimensions are incorporated in the standard dimensions.

Surface Finish Static Grooves

Straight-sided grooves are best to prevent extrusion or nibbling. Five degree sloping sides are easier to machine and are suitable for lower pressures. Surface finishes up to 64 to 125 RMS with no burrs, nicks, or scratches are recommended. The method used to produce the finish is important. If the finish is produced by machining the part on a lathe, or by some other method that produces scratches and ridges that follow the direction of the machinehead, a very rough surface will still seal effectively. Other methods, however, such as end milling, will produce scratches that cut across the o-ring. Even these may have a rather high roughness value if the profile across them shows rounded scratches that the rubber can readily flow into.