Custom & Standard Metric O-Rings

Different from a gasket, O-rings in metric sizes have round edges and are molded to fit a specific profile. They are commonly used for higher pressure and hydraulic applications and are the most common seals used in machine design because they are inexpensive and reliable.

Common metric O-rings are used for sealing applications including valves, engine components, hydraulics, faucets, pipe joints, flanges and more. They are manufactured using various types of elastomers and durometer options to meet a range of sealing requirements.

To get started, use the filters below to find the "standard" metric O-ring you need, defined by inside diameter (ID) and cross section. Then, click on the applicable link to specify your material, hardness, and color you need and request a custom quote.

Custom Metric O-Rings for All Applications

Ace Seal can provide custom metric O-rings in a broad range of sizes and cross sections, with the material, durometer, and color your project requires. Please note that not all combinations of these factors are possible—certain colors are not available in certain durometers, certain materials are not available in certain colors, etc.

We also offer AS568 O-rings, Parker 500 Series and 800 Series O-rings, back-up rings, and quad rings.

Elastomer Options for Metric O-Rings

We offer a range of elastomer options for our common metric O-rings. View our material properties comparison chart to learn more about each of the elastomers listed below. We also have a temperature compatibility chart to help you select an O-ring elastomer that meets the temperature requirements of your operating environment.

- Aflas®: Tolerates temperatures up to 400° F (204° C) and provides excellent resistance to temperatures, chemicals, acids and steam. Not for use with ketones, organic refrigerants, chlorinated hydrocarbons or aromatic fuels.

- Nitrile (Buna N): Has an operating temperature range of -40°F to 250°F (-40°C to 121°C) and a durometer range of 40 to 90. Resists air, alcohol, oils, greases and more. Not intended for use with brake fluids or acetones.

- Butyl: Operates in temperatures from -75°F to 250°F (-59°C to 121°C) and has a hardness of 70. Works well with synthetic hydraulic fluids and meets Mil-Spec and aerospace specifications.

- Ethylene-propylene: Provides and operating temperature range of -60° to 300°F (-51° to 150°C) and a hardness range of 40 to 90. Resists extreme heat and cold, steam, UV, acids and more. Do not use with solvents or aromatic hydrocarbons.

- Kalrez®: Available in several compounds providing maximum operating temperatures up to 620°F (327°C) and providing durometers ranging from 75 to 91, depending on the compound selected.

- PTFE: Provides a temperature range of -100°F to 400°F (-73°C to 204°C) and resists weather, lubricants, hydrocarbons, alcohol, ketones, acid, steam, refrigerants and more.

- PTFE-encapsulated: Feature a seamless encapsulation to provide superior chemical and temperature resistance. Contact us to discuss the different encapsulation material options and benefits.

- Silicone: Designed for temperatures ranging from -75° to 450°F (-60°C to 232°C) and provides 30 to 80 Shore A hardness with a standard hardness of 70 durometer Shore A. FDA and Mil-Spec approved and resists fungal growth, extreme temperatures, weathering and UV or ozone exposure.

- Fluorocarbon (Viton®): Operates in temperatures from -20°F to 400°F (-29°C to 204°C) and has a standard hardness of 70-78 Shore A with a hardness range of 50 to 95. Resists acids, flames, oil, weather and more.

Durometer Options for Metric O-Rings

The hardness of metric or imperial o rings is measured in durometer. A lower durometer equals a softer, more pliable material that stretches easily and can be used to seal rough or irregular surfaces. Metric O-rings with a higher durometer are stiffer but provide better resistance to abrasion that could cause a softer elastomer to fail.

- 40

- 50

- 60

- 70

- 75

- 90

- Customized hardness is also available

Color Options for Metric O-Rings

- Black

- Brown

- Rust/orange

- Translucent/clear

- Custom colors also available

Non-Standard O-Rings in Metric Sizes

Ace Seal has extensive O-ring manufacturing capabilities, including a comprehensive selection of metric and imperial sizesand elastomers to meet any sealing requirements. We offer metric O-rings in standard sizes and provide custom O-ring options using specialty materials, durometers, and/or colors.

Finding Compatible Materials and Design Options for Your Custom Metric O-Ring Seals

Temperature and chemical compatibility are critical for preventing your common metric O-rings from failing in your application. Metric O ring groove dimensions are also an important factor for determining how your metric O-ring will perform once it is installed.

Our temperature compatibility chart provides operating temperature information for all the elastomers we use to manufacture standard and custom O-rings. Our material properties comparison chart also grades each of our metric O-ring elastomers based on several properties including resistance to heat, chemicals, abrasion, water, steam, and others.

Dovetail grooves are incorporated into a design to help hold the O-ring in place during installation and maintenance. Because they can be expensive to machine, O-ring grooves should only be added when necessary or for metric O-rings with a cross-section larger than 3.53mm. Our groove design chart is a useful aid for selecting the right metric O-ring groove dimensions for your design.

Request a quote on custom metric O-rings, or contact us to discuss your unique needs.

How to Measure Metric O-Rings

There are two main O-ring sizing styles: standard and metric. Metric o rings sizes are primarily used internationally, notably in Europe and Japan. The metric sizes are based on the International Standard ISO 3601-1:2002. Metric O-ring measurements are grouped into two series: G and A. Each has a different application. The G series is used for general-purpose applications, while the A series is for Aerospace applications.

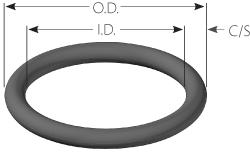

O-ring seal measurements are based on their diameters. Common metric O-rings are measured using the outside diameter (OD), inside diameter (ID), and cross-section (CS). The ID is determined by measuring the distance between two points of the inner edge of the O ring. The OD is measured by determining the distance between the OD side of the outer corner to another. And finally, the cross section is measured by subtracting the OD from the ID and dividing that number by 2. You can also measure the cross-section of metric O-ring by placing it in a Caliper and lightly clamping the jaws to record the thickness.

Metric O-ring material is measured using durometers, or the hardness of the rubber. This test measures the resistance of rubber toward indentation and provide an empirical hardness value. Different scales are used for different kinds of rubber. For softer rubber, Shore A scale is used, and Shore D scale is used for harder plastics such as PTFE.

Request a Quote for Custom Non-Standard O-Rings in Metric Sizes

We offer a wide range of custom metric and imperial O-rings in various sizes and elastomers to meet your requirements. Request a quote on custom metric O-rings, or contact us discuss your unique needs.